Double Wall Piping System

business

Let's talk

A global leader in the design, manufacturing, and supply of gas piping and tubing systems.

- +82 51 715 1290

- sales@talent-tl.com

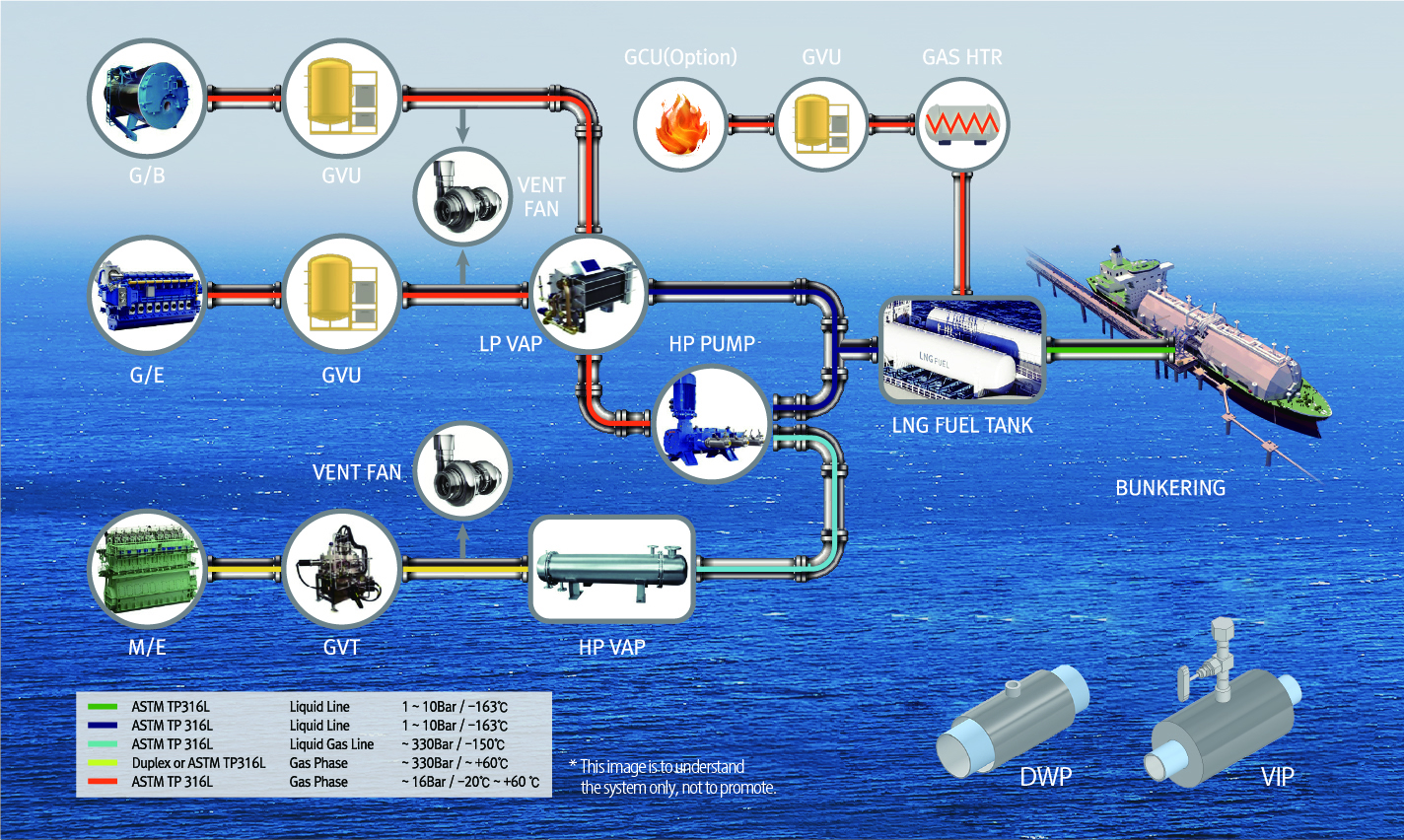

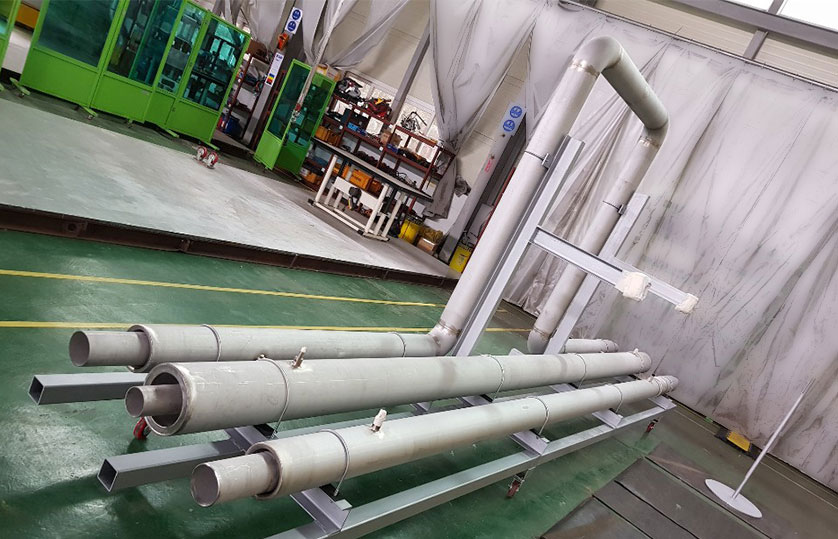

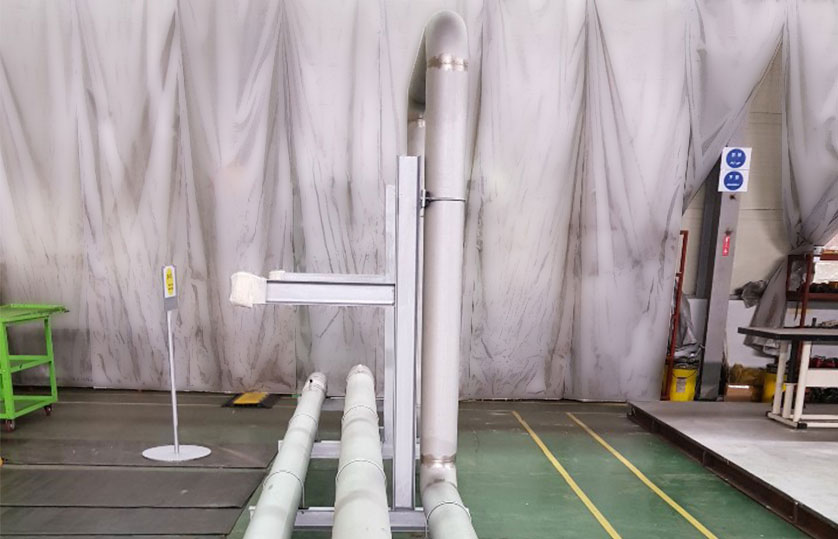

Double wall piping system

Double wall pipes are primarily designed to safely transport or store hazardous liquids and gases. Double wall pipes consist of an inner pipe and an outer pipe. This dual structure plays a critical role in reducing the risk of leaks and preventing environmental contamination.

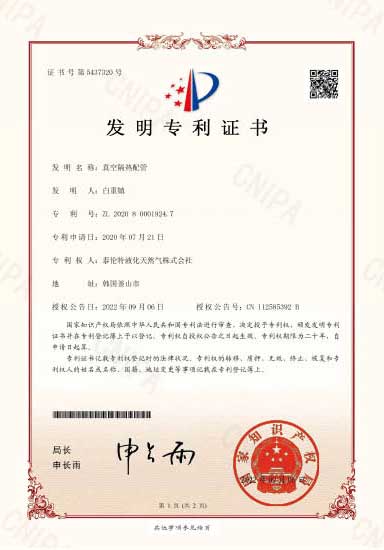

Fuel Gas Supply Piping System

Double Wall Piping System is to supply the fuel gas to main engine with purpose of protection of explosion and leak-check mainly.

Double Wall Piping has excellent performance against high pressure and extreme temperatures.

| High Pressure | Low Pressure | |

|---|---|---|

| Size | Inner Pipe DN25~60 in general Outer Pipe DN100~150 in general |

Inner Pipe DN15~300 in general Outer Pipe DN50~450 in general |

| Fluid | Natural Gas (Vaporized) | Natural Gas & Liquified Gas |

| Design Pressure | ~480Bar(g) in general | 10~16Bar(g) in general |

| Design Temperature | -50℃ ~ 60℃ in general | -20℃ ~ 60℃ in general |

| Material | Super Duplex, Duplex, Stainless Steel 316L | Stainless Steel 316L in general |

Double Wall Pipe For Main Equipment & Engines

Flange for Double Wall Pipe – Double Lip Flange

- Low Pressure & High Pressure

- Vent.holes are calculated in accordance with the air volume.

High Pressure

| Design Pressure | ~480Bar(g) in general |

| Design Temperature | -50℃ ~ 60℃ in general |

| Material | Super Duplex , Duplex, & Stainless Steel 316L |

low Pressure

| Design Pressure | 10~16Bar(g) in general |

| Design Temperature | -20℃ ~ 60℃ in general |

| Material | Stainless Steel 316L |

Vacuum Insulated Piping System

| Size | 1/2” ~ 40” |

| Design Pressure | ~ 30Bar(g) |

| Vacuum | ~5*10-6torr |

| Connection Type | Clamp & Flange Type(Bayonet Type), Welding Type |

| Fluid | LN2, LNG, LPG, LEG, LHe, LH2, LO2, LAr, & Others |

| Design Temperature | -269 ℃ ~ |

Bayonet Type

Welding Type

Vacuum gauge controller

| Type | Digital / Analog / Portable / etc. |

| Input & output signals | Various |

| Measuring range | ~5*10-9torr |

Insulation Solutions

For Insulated Piping & Vessel

- Insulation : PIF or PUF / Mineral Wool(Glass Wool & Rock Wool) / Aerogel(Cryogel, Pyrogel)

- All GTT Certified. We can supply all materials for CCS if required.

- Insulation Box & Panel : Invar / Stainless Steel Material

| No. | Designation |

| 1 | Fixing Support |

| 2 | Rigid insulating material |

| 3 | Rigid insulating material |

| 4 | Rigid insulating material |

| 5 | Plywood |

| 6 | Fixing device |

Smart Air Heating System

Smart Air Heating System maintains the best conditions for ship-engines that use LNG, LPG, LEG, and LH2 as fuel at an appropriate temperature. It is a system for improving fuel efficiency.

- Modularization

- Commissioning

- Project Consultation

- Material Selection

Projects Completed

- Welding and Assembly

- Non-Destructive Testing

- Coating and Insulation

- Advanced Manufacturing