Research and Achievements

Advancing Industry Standards through Research

At Talent LNG, our commitment to innovation is reflected in our extensive research and proven achievements. Through continuous development and rigorous testing, we have advanced LNG piping technologies and installation processes, ensuring optimal performance and client satisfaction. Our research efforts are focused on enhancing efficiency, safety, and sustainability, enabling us to set new industry standards and deliver superior solutions worldwide.

National project

| Development Task Name | Development Period | Supporting Organization |

|---|---|---|

| Development of core LNG bunkering technology and establishment of a system | 2020.04 ~ 2021.12 | Ministry of Oceans and Fisheries |

| Development of fuel pipe air heating system with active control function for LNG fuel-propelled ships operating on the Northern Sea Route | 2022.10 ~ 2023.09 | Ministry of Trade, Industry and Energy |

| Development of a vacuum-insulated double-pipe system using AI and ICT-based safety diagnostic technology for transporting ultra-low temperature liquefied hydrogen | 2023.04 ~ 2024.12 | Ministry of SMEs and Startups |

| Development of technology for collecting and separating oil-containing multiphase mixtures | 2022.04 ~ 2028.12 | Ministry of Land, Infrastructure and Transport |

Enhancing Performance

Precision Temperature Control

Smart Heating System, designed specifically to maintain the optimal temperature for ship engines using LNG, LPG, LEG, and LH2 fuels. In today’s demanding marine and offshore industries, fuel efficiency and engine reliability are critical for both performance and environmental responsibility.

- Modularization

- Commissioning

- Project Consultation

- Material Selection

Projects Completed

- Welding and Assembly

- Non-Destructive Testing

- Coating and Insulation

- Advanced Manufacturing

Safety Record

Key Components of the Smart Heating System

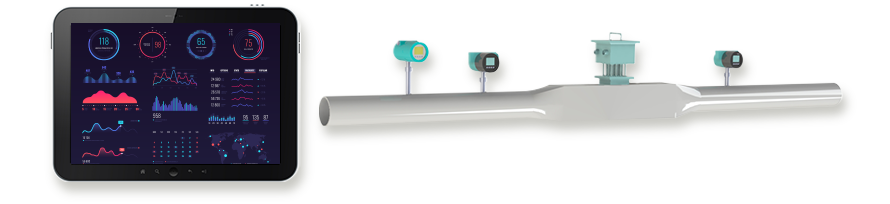

HMI Monitoring (Human-Machine Interface)

The HMI Monitoring system provides a user-friendly interface that allows operators to monitor and control the Smart Heating System from a centralized location. Through real-time data visualization, administrators can track temperature, flow rates, and overall system performance. Should any issue arise, such as temperature deviations or fuel flow disruptions, the HMI system immediately alerts users, allowing for quick responses. This ensures smooth operation and improves fuel efficiency by maintaining the best possible conditions for fuel supply.

Flow Meter

The Flow Meter is critical for monitoring the exact amount of fuel being transferred to the engine. By providing precise flow data, the Flow Meter helps to optimize fuel usage and ensures that the fuel delivery is steady and efficient. This not only prevents fuel waste but also supports the overall goal of improving fuel efficiency and engine performance.

Temperature Sensor 1

Positioned at the inlet, Temperature Sensor 1 is responsible for measuring the temperature of the fuel as it enters the system. This sensor ensures that the fuel is at the correct temperature before being transferred, which is essential for maintaining fuel efficiency and preventing engine damage. If the fuel is too cold or too warm, the system can automatically adjust to maintain the desired conditions.

Air Heater

The Air Heater plays a crucial role in maintaining the proper temperature of the fuel as it travels through the system. By providing controlled heat, the Air Heater ensures that LNG, LPG, LEG, or LH2 fuels remain within their optimal temperature range, even in cold environments. This guarantees efficient fuel combustion and enhances the safety of the entire system by reducing the risk of fuel freezing or becoming unstable.

Temperature Sensor 2

Temperature Sensor 2 is located at the outlet and monitors the temperature of the fuel just before it reaches the engine. This sensor ensures that the fuel is delivered at the precise temperature required for optimal engine performance and safety. It acts as a final checkpoint, ensuring that no irregularities in temperature exist that could affect the fuel's combustion efficiency.