Non-welded Flange System

- Completed Reliability and Cleanness

- Highly Cost Effective

- Flexible and Easy-and-Fast to Install

- Fast-and-Easy to Prefabricate Available

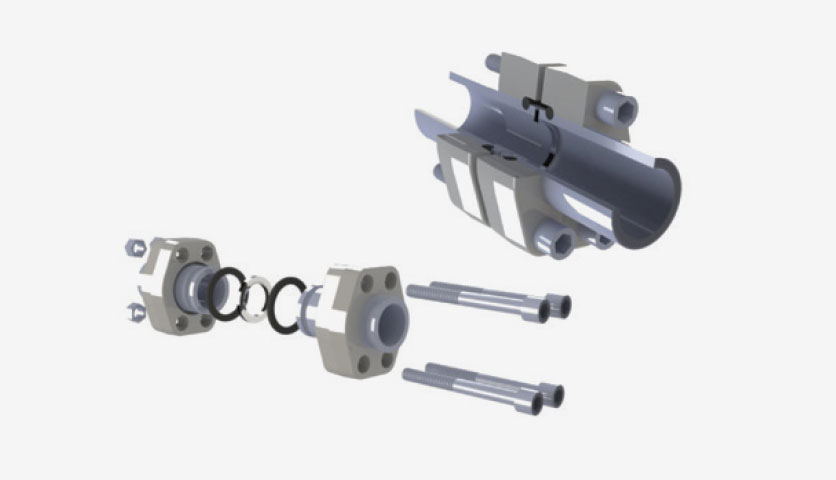

RETAIN RING FLANGE SYSTEM

Retain Ring system is used for piping with a maximum allowable working pressure of 350~420Bar(g). In special applications, this system can be used with working pressures as high as 690Bar(g). Extensive testing programs demonstrate the system for the high-pressure pipe system within the wide range of different materials ranging from carbon and stainless steel to duplex and titanium and all other quality pipe materials with an elongation above 20%.

| SAE 3000 | SAE 6000 | ISO 6164 | |

|---|---|---|---|

| Pressure(Bar(g)) | 210-350 | 420 | 210-690 |

| Pipe Size | 26x6~97x12 | 26x6~97x12 | 60.3x11.04~355.6x41.4 |

| Flange Size | 1/2”~3” | 1/2”~3” | 2”~14” |

| Pipe Material | Carbon Steel, Stainless Steel, Duplex, Super Duplex, Titanium(Materials having elongation above 20%) | ||

| Flange Material | Electric Zinced Carbon Steel, Hot Dip Galvanized Carbon Steel, Stainless Steel or Titanium | ||

| Seal Material | NBR, Viton | ||

| Retain Ring Material | Stainless Steel | ||

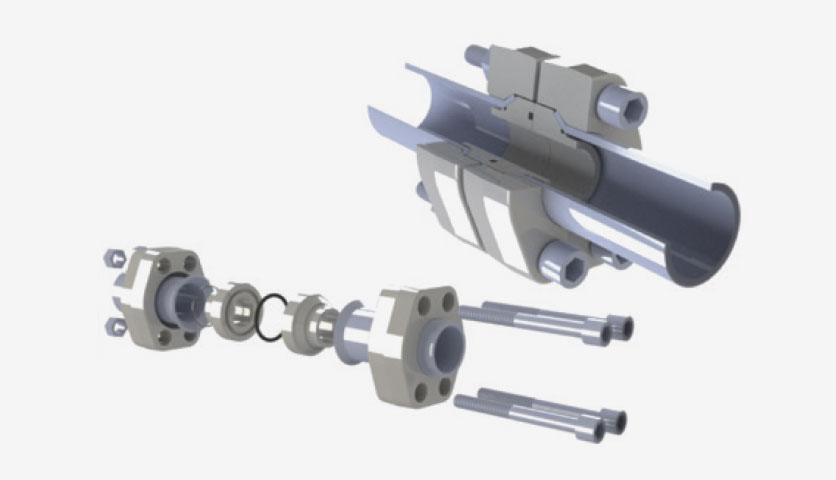

37° FLARE FLANGE SYSTEM

37° Flare Flange System is used for a wide range of high and medium pressures, which are used for a wide range of industries: Marine and Offshore, Automotive, Metals & Mining, Wood & Forestry, Pulp & Paper and Aerospace & Defense. This system is generally used within the allowable working pressure with range from 210~350Bar(g). In special applications, the system is used for piping with a maximum allowable working pressure of 420Bar(g). The 37° flare flange jointing method is suitable for high pressure piping systems in a wide range of different materials.

| SAE 50 | SAE 3000 | SAE 6000 | ISO 6164 | |

|---|---|---|---|---|

| Pressure(Bar(g)) | ‹ 50 | 210~350 | 420 | 350~400 |

| Pipe Size | 50x3~273x6 | 16x2~90x5 | 16x2~90x9 | 50x5~90x9 |

| Flange Size | 1 1/2”~10” | 1/2”~3” | 1/2”~3” | 1 1/2”~3” |

| Pipe Material | Carbon Steel, Stainless Steel, Duplex, Super Duplex, Titanium(Materials having elongation above 20%) | |||

| Flange Material | Electric Zinced Carbon Steel, Hot Dip Galvanized Carbon Steel, Stainless Steel or Titanium | |||

| Insert Cone Material | Electric Zinced Carbon Steel, Stainless Steel | |||

| Seal Material | NBR, Viton | |||

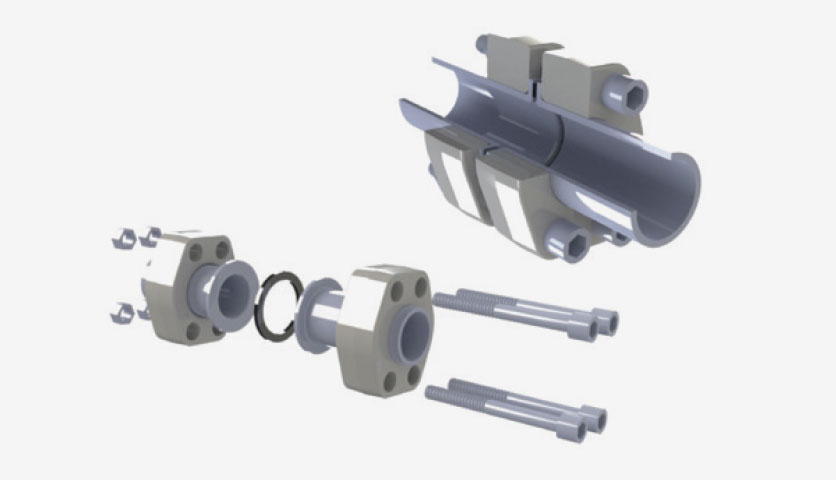

90° FLARE FLANGE SYSTEM

In GS-90° Flare Flange System, the end of the tube is clamped into a flaring machine where a conical rotating tool flares the pipe end into a die. A seal is placed between the pipe ends and the flanges are then tightened together to complete the connection. The System is used for class III piping with a maximum allowable working pressure of 16Bar(g). The GS-90° Flare Flange Jointing method is suitable for low pressure piping systems in a wide range of different materials ranging from mild steel to super duplex. The System can be utilized for low pressure piping systems(10~40Bar(g)) and for pipes with a maximum diameter of 608mm.

| SAE | ANSI/JIS/BS/DIN | |

|---|---|---|

| Pressure(Bar(g)) | 10~40 | 10~40 |

| Pipe Size | 16x1.5~220x6 | 21.3x2.1~608x12.5 |

| Flange Size | 1/2”~8” | 1/2”~24” |

| Pipe Material | Carbon steel, galvanized steel, copper-nickel, aluminum/brass, duplex, super duplex, titanium (Materials having elongation above 20%) | |

| Flange Material | Electric zinced carbon steel, hot dip galvanized carbon steel, stainless steel | |

| Seal Material | Based on media inside pipe (example Klinger SIL C-4430) | |

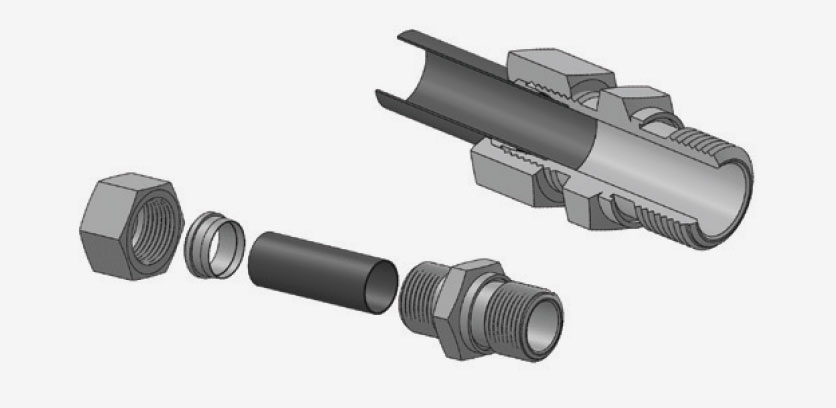

Non-welded Fitting System

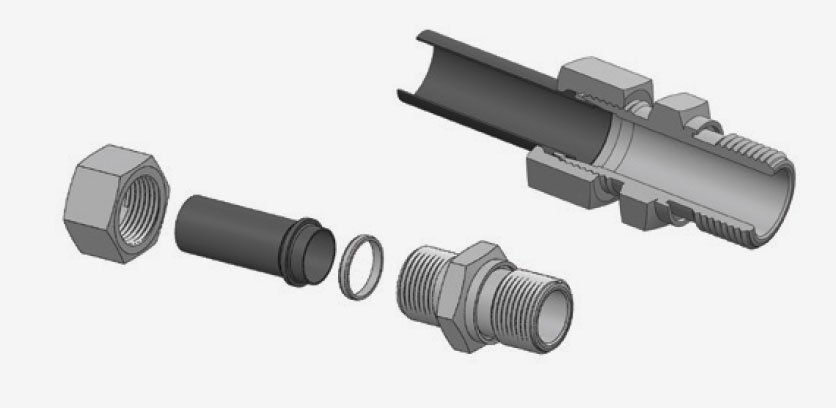

DIN2353 Cutting System

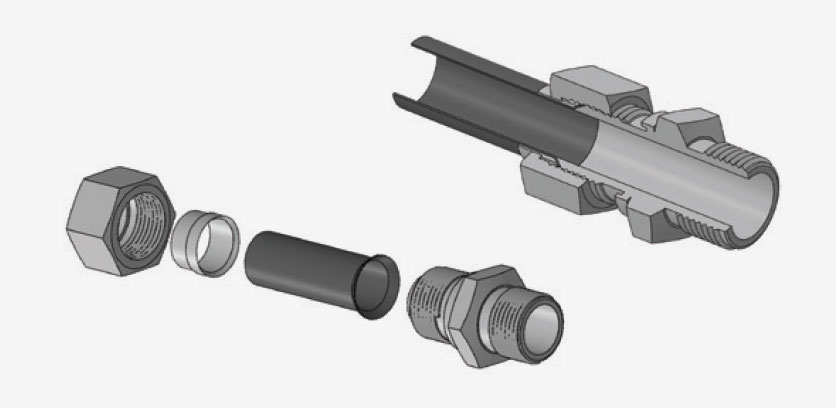

DIN2353 Walform

37° Flare

BENEFIT – Non-welded Fitting System

- Best-in-Class Pressure Performance

- Connections Meeting Industry Specifications

- Enhanced Cost-Effectiveness due to Increased Pressure Resistance

- Easy and Safe Assembly